Why AC motor needs a Frequency Converter?

What is a frequency converter?

Simply words, a frequency converter is a power conversion device. The frequency converter converts a basic fixed-frequency, fixed voltage sine-wave power (line power) to a variable-frequency, variable-voltage output used to control speed of induction motors.

Why use a frequency converter?

Primary function of a frequency converter in aquatic applications is to provide energy savings. By controlling speed of a pump rather than controlling flow through use of throttling valves, energy savings can be substantial. By way of example, a speed reduction of 20% can yield energy savings of 50%. The following describes speed reduction and corresponding energy savings. In addition to energy savings, impeller, bearing and seal life is greatly improved.

Primary function of a frequency converter in aquatic applications is to provide energy savings. By controlling speed of a pump rather than controlling flow through use of throttling valves, energy savings can be substantial. By way of example, a speed reduction of 20% can yield energy savings of 50%. The following describes speed reduction and corresponding energy savings. In addition to energy savings, impeller, bearing and seal life is greatly improved.Frequency converters

Available in many different types, frequency converters offer optimum method for matching pump and fan flow rates to system requirements. Frequency converter is most commonly used. It converts standard plant power (220V or 380 V, 50 Hz) to adjustable voltage and frequency to power AC motor. The frequency applied to AC motor determines motor speed. The AC motors are usually same standard motors that can be connected across AC power line. By incorporating bypass starters, operation can be maintained even if inverter should fail.

Frequency converters also offer an additional benefit - increased bearing and pump seal life. By maintaining only pressure needed in pump to satisfy system requirements, pump is not subjected to any higher pressures than necessary. Therefore, the components last longer.

The same benefits - but to a lesser extent - also apply to fans operated by frequency converters.

To obtain optimum efficiencies and reliability, many specifiers obtain detailed information from manufacturers on frequency converter efficiency, required maintenance, diagnostic capabilities within frequency converter, and general operational features. Then, they make detailed analysis to determine which system will give the best return on investment.

Additional Benefits of frequency converters

In addition to energy savings and better process control, frequency converters can provide other benefits:

- A frequency converter may be used for control of process temperature, pressure or flow without use of a separate controller. Suitable sensors and electronics are used to interface driven equipment with frequency converter.

- Maintenance costs can be lowered, since lower operating speeds result in longer life for bearings and motors.

- Eliminating throttling valves and dampers also does away with maintaining these devices and all associated controls.

- A soft starter for motor is no longer required.

- Controlled ramp-up speed in a liquid system can eliminate water hammer problems.

- Ability of a frequency converter to limit torque to a user-selected level can protect driven equipment that cannot tolerate excessive torque.

Analyze System as a Whole

Since process of converting incoming power from one frequency to another will result in some losses, energy savings must always come from optimizing performance of the complete system. First step in determining energy savings potential of a system is to thoroughly analyze operation of entire system. Detailed knowledge of equipment operation and process requirements are required in order to ensure energy savings. In addition, type of frequency converter, features offered, and overall suitability for application should be considered.

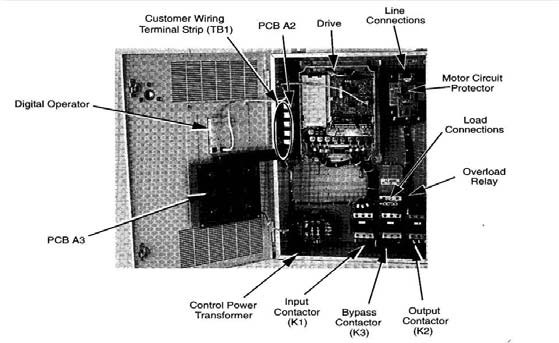

Frequency Converter Internal Configuration

Frequency converters contain three primary sections:

- Rectifier Circuit - consists of diodes, SCRs, or insulated gate bipolar transistors. These devices convert AC line power to direct current.

- DC Bus - consists of capacitors that filter and store the DC charge.

- Inverter - consists of high-voltage, high-power transistors that convert DC power to a variable-frequency, variable-voltage AC output delivered to load.

Frequency converters also contain a powerful microprocessor which controls inverter circuit to produce an almost pure variable-frequency sinusoidal voltage delivered to load. The microprocessor also controls input / output configurations, frequency converter settings, fault conditions and communication protocols.

High quality frequency inverters for electric motor speed controls in energy-saving solutions.

High quality frequency inverters for electric motor speed controls in energy-saving solutions.