Frequency inverter reconstruction to save energy

Frequency inverter reconstruction of Power Plant promoted heightening of economy benefit. Frequency inverter won acceptance of user as its high reliability, flexible adjustment and simple operation.

A Power Plant was set up in June, 2000. Its predecessor was one of key plants of state. The plant put into service in 1957. Now it has 4×50MW, 2×142MW, total ten boilers and six generators. Total capacity is 484MW. The plant supplies power to big enterprise near to it.

In the power plant, for main equipments, such as FD fan, ID fan, feed pump and circulating pump, output power cannot change with load variety. Damper control or valve control causes much energy waste. Therefore, energy saving and emission reduction are brought up on the agenda. Power plant is in search of way of energy saving in term of technology.

Making technology reconstruction for main equipment by medium voltage variable frequency technology is an effective method of energy saving.

Problems of recycle water system

During reconstruction of ventilation cooling tower of circulating water system in 2001, power plant reduced circulating water flow to 5000t/h from 10000t/h, which lowered cost of power generating, and gained evident economy benefit. But there was a problem. Four sets of axis flow recycle pump (rated output 9720m3/h) were equipped for inlet of tower specially. Output of pump was too big, which could not match with water tower.

As is well known, performance curve of axis pump is very steep. Pipe resistance variety affects little on flow variety. Outlet gate of the pump and inlet gate of well can not be throttled, which leads to difficult adjustment of flow. Thus flow adjustment only depends on adjusting condenser outlet gate, starting/stopping circulating pump and increasing/decreasing primary water flow. That is not convenient at all. Furthermore, it is wasteful. For example, in winter, temperatures of circulating water inlet and outlet are low. If a recycle pump runs in rated condition, in order to ensure pump inlet normal, output gates of all machines open big. In the meantime, in order to maintain main pipe pressure, circulating pump needs to starts, which increases power consumption. In summer, because of high temperature of coming water, primary water flow increases to ensure temperature of air discharge not too high. Condenser opening is also big, causing #3, 4 water level flooding. Starting recycle pump would oblige condenser outlet gate big opening. All eight circulating pumps starting can not ensure #3, 4 water level. Furthermore, starting circulating pump and increasing primary flow lead to cost rising.

Install frequency inverter on #1, 3 recycle pump according to actual state and strategy of sustainable develoment.

System parameters and control logic

After comparisons and researches, power plant selected Gozuk frequency inverter at last.

1. Parameters of motor and pump

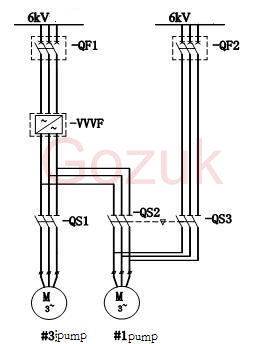

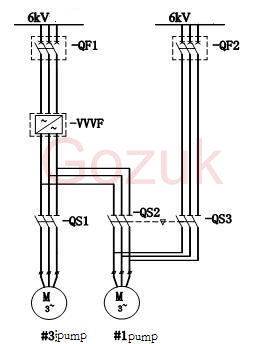

2. Bypass scheme:

Components:

QF1, QF2: medium voltage breaker

QS1, QS2, QS3: manual isolator

VVVF: medium voltage frequency inverter

M1, M2: 710kW/6kV asynchronous motor

Operation mode:

"One drive two" scheme (one pump work, one pump standby)

#3 pump runs only in variable frequency. 1# pump can run in direct on line

3. Frequency inverter

#1 and #3 recycle pump involve in following circulating course: draw water of storage tank to cold water tower. Water of tower is used for production. Residual water returns to storage tank.

Install frequency inverter ahead of motor to boost adjustment. frequency inverter adopts new model power cell. It implements digital computer control by power cell and programme control. frequency inverter has advantages of high reliability and simple operation, applicable to power plant.

Originally, one pump drew less water, causing water flooding, about 5000m3/h. After using frequency inverter, two pumps work at 35Hz together, maintaining water level at 4.8m. No water flooding caused. In addition, frequency inverter also accelerates circulating course, lowers coal consumption.

Energy saving and application

1. Energy saving effect

a. Compare economy index of October 2002 and October 2003. Average load is 12.8MW

October 2002: average vacuum: 90.26%, primary water flow: 5000t/h

October 2003: average vacuum: 93.37%, primary water flow: 3500t/h

b. Calculation of a month

October 2002: cost of primary water: 5000×24×31×0.4=1488000yuan

October 2003: cost of primary water: 3500×24×31×0.4=1041600yuan

Cost saved: 446400yuan(USD 65647)

c. Vacuum of October 2002: 90.26%, corresponding air discharge temperature: 42℃

Vacuum of October 2003: 93.37%, corresponding air discharge temperature: 35℃

From comparison, air discharge temperature lowered 7℃. When vacuum heightened 1%, there was coal consumption 3.5g/kW•h saved. So compared with vacuum of October 2002, vacuum heightened 3.11% in October 2003. Coal consumption 10.9g/kW.h was saved. Power generating is 94950000kW.h in the month, coal saved: 94950000×10.9×0.8=827.96t×210yuan/t =173900yuan (USD25573)

d. After using frequency inverter, monthly power consumption is just 130000kW.h more than mode of single pump work in direct on line. Cost: 130000×0.196=25500yuan (USD3750)

e. So monthly economy benefit: 446400+173900-25500=594800yuan, yearly economy benefit: 59.48×12=7137600yuan (USD 1049647)

2. Advantages of frequency inverter during application

a. frequency inverter reconstruction reduces times of pump start/stop, keeps system reliable, lowers adjustment difficulty.

b. frequency inverter improves adjustment flexibility. It is convenient for cleaning glue ball of condenser. Originally, this work demanded primary water. During the course, increasing/decreasing primary water, starting/stopping circulating pump lead to circulating water waste. Variable frequency pump meets water level demand by adjusting motor frequency.

c. In summer, starting variable frequency pump can increase inlet water, heighten cooling efficiency of tower, which avoids flooding, increases circulating rate of cooling water, lowers air discharge temperature, improves thermal economic.

In winter, when water temperature is low, just starting one variable frequency pump can ensure reliable temperature of air discharge, heighten system safety, decrease primary water and power consumption, which lowers cost and enhances benefit.

3. Comprehensive benefit

Frequency inverter has been running stably since it put into service in September, 2003. Controllability of circulating system heightens greatly. Frequency inverter not only saves much power but also lowers primary water, reduces times of pump start/stop. It also improves vacuum, decreases coal consumption. Thereby, this project got second prize of science & technology achievement and first prize of Power Plant science & technology development.

Conclusion

As a new speed adjustment mode, medium voltage frequency inverter has advantages over other speed adjustment modes. It is main control method of energy saving in big power plant. Frequency inverter reconstruction promotes economy benefit and wins user acceptance as its high reliability and flexible adjustment.

The Power Plant will make frequency inverter construction for water pumps, which must optimize resource allocation, creates conditions for sustainable development.

A Power Plant was set up in June, 2000. Its predecessor was one of key plants of state. The plant put into service in 1957. Now it has 4×50MW, 2×142MW, total ten boilers and six generators. Total capacity is 484MW. The plant supplies power to big enterprise near to it.

In the power plant, for main equipments, such as FD fan, ID fan, feed pump and circulating pump, output power cannot change with load variety. Damper control or valve control causes much energy waste. Therefore, energy saving and emission reduction are brought up on the agenda. Power plant is in search of way of energy saving in term of technology.

Making technology reconstruction for main equipment by medium voltage variable frequency technology is an effective method of energy saving.

Problems of recycle water system

During reconstruction of ventilation cooling tower of circulating water system in 2001, power plant reduced circulating water flow to 5000t/h from 10000t/h, which lowered cost of power generating, and gained evident economy benefit. But there was a problem. Four sets of axis flow recycle pump (rated output 9720m3/h) were equipped for inlet of tower specially. Output of pump was too big, which could not match with water tower.

As is well known, performance curve of axis pump is very steep. Pipe resistance variety affects little on flow variety. Outlet gate of the pump and inlet gate of well can not be throttled, which leads to difficult adjustment of flow. Thus flow adjustment only depends on adjusting condenser outlet gate, starting/stopping circulating pump and increasing/decreasing primary water flow. That is not convenient at all. Furthermore, it is wasteful. For example, in winter, temperatures of circulating water inlet and outlet are low. If a recycle pump runs in rated condition, in order to ensure pump inlet normal, output gates of all machines open big. In the meantime, in order to maintain main pipe pressure, circulating pump needs to starts, which increases power consumption. In summer, because of high temperature of coming water, primary water flow increases to ensure temperature of air discharge not too high. Condenser opening is also big, causing #3, 4 water level flooding. Starting recycle pump would oblige condenser outlet gate big opening. All eight circulating pumps starting can not ensure #3, 4 water level. Furthermore, starting circulating pump and increasing primary flow lead to cost rising.

Install frequency inverter on #1, 3 recycle pump according to actual state and strategy of sustainable develoment.

System parameters and control logic

After comparisons and researches, power plant selected Gozuk frequency inverter at last.

1. Parameters of motor and pump

| Motor parameter | Pump parameter | ||

| Model | YKKL560-10 | Model | 1200HTEX |

| manufacturer | Xiangtan Motor Plant | Manufacturer | Shenyang Pump Plant |

| Rated voltage | 6kV | Flow | 9720t/h |

| Rated power | 710kW | Lift | 18m |

| Rated current | 83A |

|

|

| Rated speed | 591r/min |

|

|

2. Bypass scheme:

Components:

QF1, QF2: medium voltage breaker

QS1, QS2, QS3: manual isolator

VVVF: medium voltage frequency inverter

M1, M2: 710kW/6kV asynchronous motor

Operation mode:

"One drive two" scheme (one pump work, one pump standby)

#3 pump runs only in variable frequency. 1# pump can run in direct on line

3. Frequency inverter

#1 and #3 recycle pump involve in following circulating course: draw water of storage tank to cold water tower. Water of tower is used for production. Residual water returns to storage tank.

Install frequency inverter ahead of motor to boost adjustment. frequency inverter adopts new model power cell. It implements digital computer control by power cell and programme control. frequency inverter has advantages of high reliability and simple operation, applicable to power plant.

Originally, one pump drew less water, causing water flooding, about 5000m3/h. After using frequency inverter, two pumps work at 35Hz together, maintaining water level at 4.8m. No water flooding caused. In addition, frequency inverter also accelerates circulating course, lowers coal consumption.

Energy saving and application

1. Energy saving effect

a. Compare economy index of October 2002 and October 2003. Average load is 12.8MW

October 2002: average vacuum: 90.26%, primary water flow: 5000t/h

October 2003: average vacuum: 93.37%, primary water flow: 3500t/h

b. Calculation of a month

October 2002: cost of primary water: 5000×24×31×0.4=1488000yuan

October 2003: cost of primary water: 3500×24×31×0.4=1041600yuan

Cost saved: 446400yuan(USD 65647)

c. Vacuum of October 2002: 90.26%, corresponding air discharge temperature: 42℃

Vacuum of October 2003: 93.37%, corresponding air discharge temperature: 35℃

From comparison, air discharge temperature lowered 7℃. When vacuum heightened 1%, there was coal consumption 3.5g/kW•h saved. So compared with vacuum of October 2002, vacuum heightened 3.11% in October 2003. Coal consumption 10.9g/kW.h was saved. Power generating is 94950000kW.h in the month, coal saved: 94950000×10.9×0.8=827.96t×210yuan/t =173900yuan (USD25573)

d. After using frequency inverter, monthly power consumption is just 130000kW.h more than mode of single pump work in direct on line. Cost: 130000×0.196=25500yuan (USD3750)

e. So monthly economy benefit: 446400+173900-25500=594800yuan, yearly economy benefit: 59.48×12=7137600yuan (USD 1049647)

2. Advantages of frequency inverter during application

a. frequency inverter reconstruction reduces times of pump start/stop, keeps system reliable, lowers adjustment difficulty.

b. frequency inverter improves adjustment flexibility. It is convenient for cleaning glue ball of condenser. Originally, this work demanded primary water. During the course, increasing/decreasing primary water, starting/stopping circulating pump lead to circulating water waste. Variable frequency pump meets water level demand by adjusting motor frequency.

c. In summer, starting variable frequency pump can increase inlet water, heighten cooling efficiency of tower, which avoids flooding, increases circulating rate of cooling water, lowers air discharge temperature, improves thermal economic.

In winter, when water temperature is low, just starting one variable frequency pump can ensure reliable temperature of air discharge, heighten system safety, decrease primary water and power consumption, which lowers cost and enhances benefit.

3. Comprehensive benefit

Frequency inverter has been running stably since it put into service in September, 2003. Controllability of circulating system heightens greatly. Frequency inverter not only saves much power but also lowers primary water, reduces times of pump start/stop. It also improves vacuum, decreases coal consumption. Thereby, this project got second prize of science & technology achievement and first prize of Power Plant science & technology development.

Conclusion

As a new speed adjustment mode, medium voltage frequency inverter has advantages over other speed adjustment modes. It is main control method of energy saving in big power plant. Frequency inverter reconstruction promotes economy benefit and wins user acceptance as its high reliability and flexible adjustment.

The Power Plant will make frequency inverter construction for water pumps, which must optimize resource allocation, creates conditions for sustainable development.

High quality frequency inverters for electric motor speed controls in energy-saving solutions.

High quality frequency inverters for electric motor speed controls in energy-saving solutions.