Frequency inverter in Oil Industry

This application states energy saving reconstruction on ID fan and FD fan of 4# boiler in a Chinese Oil Industry Company, introduces reconstruction purpose, scheme, implementation and principle. It analyses reconstruction effect, especially the economy effect, illustrates meaning of reconstruction. Variable frequency adjustment is an effective way of source saving management.

The plant has three 75t boilers, three 220t boilers. 1#, 2# and 3# boilers are 75t. 4#, 5#, and 6# boilers are 220t. Six boilers all equip ID fan, FD fan and SA fan. The motors of fans are designed as per max load. But boilers run in max load in very short time and they run at 66% load mostly. So actual air flow of boiler demand is not max flow but variable flow which varies with load changing. In order to meet air flow requirement, we use conventional damper adjustment. This way can change air flow but cannot change motor speed as well as save energy, causing much energy waste and cost rising.

Reconstruction purpose

In order to lower production cost and power consumption, variable frequency technology should be adopted. By utilizing low voltage frequency inverter, the plant has gained considerable energy saving effect and maintenance experience. With maturity of medium voltage frequency inverter, we utilize this technology outcome to medium voltage motor. We reformed for three fans of 4# boiler in May, 2006.

Parameters of fans

Reconstruction scheme

1. frequency inverter selection

After comparing and analyzing, the plant selected Gozuk frequency inverter eventually.

2. Main circuit

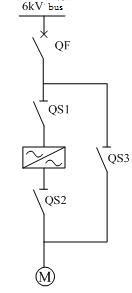

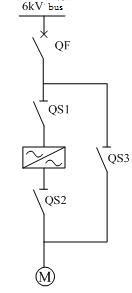

We decided to adopt "one drive one" scheme due to importance of fan. That is, one frequency inverter drives one motor of fan. In order to improve reliability and safety, we add bypass circuit. Please see the figure.

QF is vacuum breaker. QS1, QS2 and QS3 are medium voltage isolator. Medium voltage frequency inverter is between QS1 and QS2. QS3 is bypass switch. When motor needs to run in variable frequency, open QS3 and close QS1, QS2, then close QF. When motor needs to run in direct on line, open QS1, QS2, close QS3 and then close QF. In this way, motor can run in direct on line during frequency inverter downtime or maintenance.

Above scheme is typical manual scheme. QS2 and QS3 interlock in mechanism and they cannot close simultaneously.

In order to realize fault frequency inverter protection, frequency inverter sends trip command when it faults seriously and link trips medium voltage breaker to make frequency inverter off power. In the meantime, three switches interlock electrically with QF. Only when breaker is off, can personnel operate switch, which ensures safety.

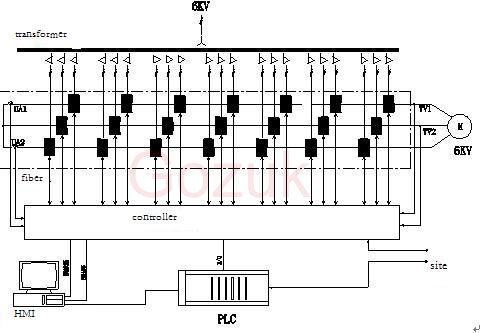

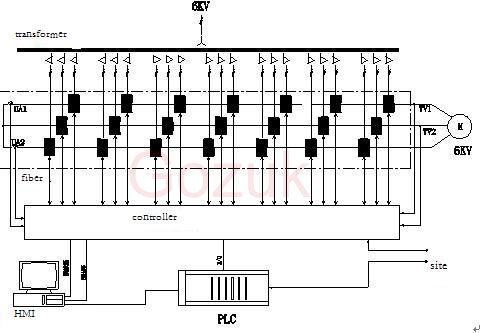

3. Control scheme

According to actual state, we adopt three control schemes. They are DCS close loop control, DCS open loop control and local control.

4. Cooling scheme

Principle of frequency inverter is to rectify AC to DC and invert DC to AC. During this course, electric components emit heat (2%). The heat causes equipment temperature up and damages equipment. In order to ensure stable work of frequency inverter, the heat must be dissipated outside. So cooling scheme is very important. After researching carefully, we adopt the most effective and easiest scheme---air cooling. Install air duct on top of frequency inverter. The duct discharges the heat outside. The scheme only needs a duct without other device, so it is simple and reliable with few failure factor. Make full load test at 40℃. Max temperature of frequency inverter reaches to 68℃. Compared with max design temperature-rising, the result is ideal.

Reconstruction effect

1. Technics effect after reconstruction

After reconstruction, damper opening is 100%, which reduces resistance loss a lot. Because motor runs in variable frequency, fixed resonance frequency is difficult to be line with operation frequency, thereby resonance can be avoided. So problem of pipeline breakage is solved naturally. This is also an unexpected benefit.

2. Impact on power grid

If motor starts in direct on line, start current is 7~8 times of rated current. Big current increases electrical force and creates heat, which shortens motor lifetime. In variable frequency system, motor realizes soft start. Motor can start at zero speed and accelerates to operation current gradually. Frequency inverter drives load in V/f control or vector control without impact on power grid.

3. Maintenance labour after reconstruction

After reconstruction, motor usually runs in 30Hz~40Hz. Compared with line frequency 50Hz, fan speed lowers. In addition, slow accelerating prolongs equipment lifetime. Damper lifetime is also prolonged. Maintenance labour reduces and maintenance cost reduces too.

4. Energy saving effect

Please see following data:

Note: power factor is 0.85 before reconstruction and 0.97 after reconstruction.

From above data, during operation from 140t to 200t, we see energy saved reduces with load increasing and increases with load decreasing. Boiler works in 140t~150t for about 8 months, in 200t just for 2 months, in 180t for 1 month, maintenance for 1 month. Power consumption of three fans of 4# boiler is about 18631338.7kWh before reconstruction and 9411516.9kWh after reconstruction. Yearly power saved is 9219821.9 kWh, energy saving rate is 49.5%. that is to say, we can approach production task by 50.5% of power consumption before. Power price is 0.45yuan/kWh, yearly cost saved is 4148919.8yuan (USD610135). The investment is recovered within the year.

Conclusion

The reconstruction of 4# boiler was an important project in 2006. The project is specific measure of transferring from extensive management to saving management, is a great stride on energy saving. Technics effect and energy saving effect inspire positivity of staff. In the meantime, it indicates enormous potential of energy saving.

The plant has three 75t boilers, three 220t boilers. 1#, 2# and 3# boilers are 75t. 4#, 5#, and 6# boilers are 220t. Six boilers all equip ID fan, FD fan and SA fan. The motors of fans are designed as per max load. But boilers run in max load in very short time and they run at 66% load mostly. So actual air flow of boiler demand is not max flow but variable flow which varies with load changing. In order to meet air flow requirement, we use conventional damper adjustment. This way can change air flow but cannot change motor speed as well as save energy, causing much energy waste and cost rising.

Reconstruction purpose

In order to lower production cost and power consumption, variable frequency technology should be adopted. By utilizing low voltage frequency inverter, the plant has gained considerable energy saving effect and maintenance experience. With maturity of medium voltage frequency inverter, we utilize this technology outcome to medium voltage motor. We reformed for three fans of 4# boiler in May, 2006.

Parameters of fans

| Fan | Motor model | Rated voltage | Rated current | Rated power | Power factor | Rated speed |

| PA fan | YFKK5004-4 | 6000V | 131A | 1120kW | 0.85 | 1490r/min |

| SA fan | YFKK5001-4 | 6000V | 94A | 800kW | 0.85 | 1490r/min |

| 1# ID fan | YFKK4505-6W | 6000V | 61A | 500kW | 0.85 | 990r/min |

Reconstruction scheme

1. frequency inverter selection

After comparing and analyzing, the plant selected Gozuk frequency inverter eventually.

2. Main circuit

We decided to adopt "one drive one" scheme due to importance of fan. That is, one frequency inverter drives one motor of fan. In order to improve reliability and safety, we add bypass circuit. Please see the figure.

QF is vacuum breaker. QS1, QS2 and QS3 are medium voltage isolator. Medium voltage frequency inverter is between QS1 and QS2. QS3 is bypass switch. When motor needs to run in variable frequency, open QS3 and close QS1, QS2, then close QF. When motor needs to run in direct on line, open QS1, QS2, close QS3 and then close QF. In this way, motor can run in direct on line during frequency inverter downtime or maintenance.

Above scheme is typical manual scheme. QS2 and QS3 interlock in mechanism and they cannot close simultaneously.

In order to realize fault frequency inverter protection, frequency inverter sends trip command when it faults seriously and link trips medium voltage breaker to make frequency inverter off power. In the meantime, three switches interlock electrically with QF. Only when breaker is off, can personnel operate switch, which ensures safety.

3. Control scheme

According to actual state, we adopt three control schemes. They are DCS close loop control, DCS open loop control and local control.

4. Cooling scheme

Principle of frequency inverter is to rectify AC to DC and invert DC to AC. During this course, electric components emit heat (2%). The heat causes equipment temperature up and damages equipment. In order to ensure stable work of frequency inverter, the heat must be dissipated outside. So cooling scheme is very important. After researching carefully, we adopt the most effective and easiest scheme---air cooling. Install air duct on top of frequency inverter. The duct discharges the heat outside. The scheme only needs a duct without other device, so it is simple and reliable with few failure factor. Make full load test at 40℃. Max temperature of frequency inverter reaches to 68℃. Compared with max design temperature-rising, the result is ideal.

Reconstruction effect

1. Technics effect after reconstruction

After reconstruction, damper opening is 100%, which reduces resistance loss a lot. Because motor runs in variable frequency, fixed resonance frequency is difficult to be line with operation frequency, thereby resonance can be avoided. So problem of pipeline breakage is solved naturally. This is also an unexpected benefit.

2. Impact on power grid

If motor starts in direct on line, start current is 7~8 times of rated current. Big current increases electrical force and creates heat, which shortens motor lifetime. In variable frequency system, motor realizes soft start. Motor can start at zero speed and accelerates to operation current gradually. Frequency inverter drives load in V/f control or vector control without impact on power grid.

3. Maintenance labour after reconstruction

After reconstruction, motor usually runs in 30Hz~40Hz. Compared with line frequency 50Hz, fan speed lowers. In addition, slow accelerating prolongs equipment lifetime. Damper lifetime is also prolonged. Maintenance labour reduces and maintenance cost reduces too.

4. Energy saving effect

Please see following data:

| Steam flow T/H | PA fan current | SA fan current | ID fan current | Total current difference(A) | Total Power difference | ||||||

| Before (A) | After (A) | Difference (kW) | Before (A) | After (A) | Difference (kW) | Before (A) | After (A) | Difference (kW) | |||

| 140 | 123 | 50.1 | 610.5 | 77 | 30.3 | 393.5 | 50 | 18.4 | 269.0 | 151.2 | 1273.0 |

| 145 | 123 | 50.6 | 605.2 | 77 | 30.8 | 388.2 | 50 | 19.1 | 261.6 | 149.5 | 1255.0 |

| 150 | 124 | 53.7 | 581.7 | 78 | 31.4 | 391.1 | 51 | 20.1 | 260.3 | 146.8 | 1233.1 |

| 155 | 124 | 55.1 | 566.9 | 79 | 32.8 | 385.6 | 52 | 21.6 | 253.7 | 145.5 | 1206.1 |

| 160 | 125 | 60.2 | 522.2 | 80 | 35.1 | 370.5 | 52 | 27.4 | 192.3 | 133.3 | 1085.0 |

| 165 | 125 | 60.9 | 514.8 | 82 | 36 | 379.5 | 52 | 28.9 | 176.4 | 133.2 | 1070.7 |

| 170 | 126 | 61.1 | 521.9 | 82 | 37.5 | 363.6 | 52 | 34.1 | 121.4 | 127.3 | 1006.9 |

| 180 | 126 | 61.1 | 521.9 | 82 | 38.3 | 355.2 | 52 | 38.2 | 78.0 | 122.4 | 955.1 |

| 190 | 129 | 62 | 540.2 | 82 | 39 | 347.8 | 52 | 43 | 27.2 | 119 | 915.2 |

| 200 | 131 | 62 | 558.8 | 82 | 39.7 | 340.3 | 52 | 45 | 6.0 | 118.3 | 905.1 |

From above data, during operation from 140t to 200t, we see energy saved reduces with load increasing and increases with load decreasing. Boiler works in 140t~150t for about 8 months, in 200t just for 2 months, in 180t for 1 month, maintenance for 1 month. Power consumption of three fans of 4# boiler is about 18631338.7kWh before reconstruction and 9411516.9kWh after reconstruction. Yearly power saved is 9219821.9 kWh, energy saving rate is 49.5%. that is to say, we can approach production task by 50.5% of power consumption before. Power price is 0.45yuan/kWh, yearly cost saved is 4148919.8yuan (USD610135). The investment is recovered within the year.

Conclusion

The reconstruction of 4# boiler was an important project in 2006. The project is specific measure of transferring from extensive management to saving management, is a great stride on energy saving. Technics effect and energy saving effect inspire positivity of staff. In the meantime, it indicates enormous potential of energy saving.

High quality frequency inverters for electric motor speed controls in energy-saving solutions.

High quality frequency inverters for electric motor speed controls in energy-saving solutions.